A pick list is a collection of products that belong to multiple orders. Suppose you want to pick 10 orders: you then gather all the products associated with these orders. Once you have picked everything, you can pack the orders quickly and efficiently.

One universal pick list in ShopLinkr

Within ShopLinkr, we have developed one universal pick list that allows you to process orders quickly and clearly. Whether you work with different bins or collect everything in one bin: the system adapts to your working method.

How to generate a pick list?

You can easily generate a pick list via:

Orders → Pick Lists → Generate Pick List

On this page, you can filter by:

Orders from specific sales channels (such as your webshop)

Product locations within your warehouse

Only single orders or not

Only certain products

Tags

Package type

Pickup time (bol VVB complete)

Order date

These filters help you to pick selectively and efficiently.

Start picking

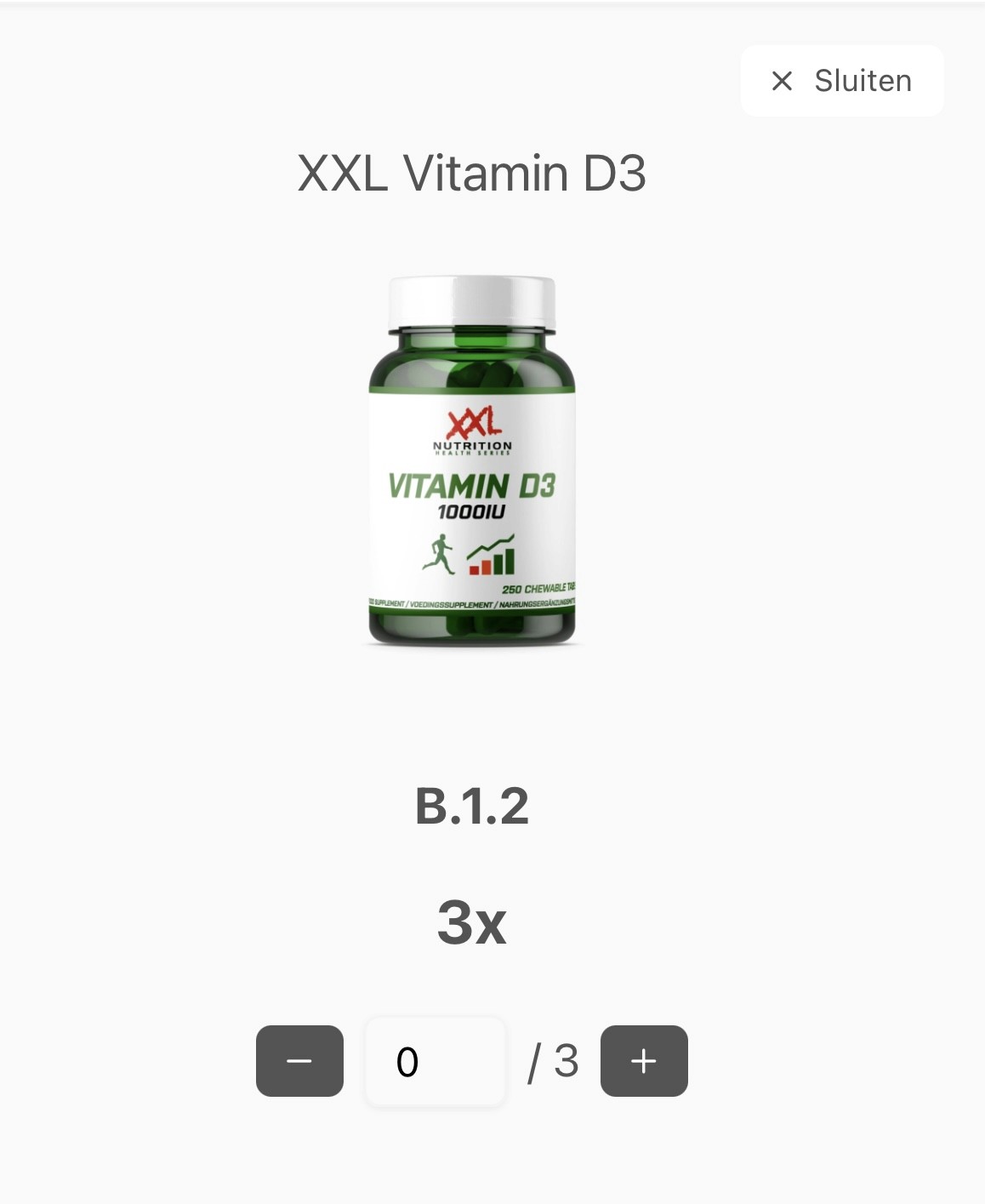

Once you have created the pick list, you can start picking. It works best to do this on a handheld scanner. On this, you see:

Which product you need to pick

Where it is located in your warehouse

You scan the product (or manually add it). After a successful scan, you automatically move to the next product. This way, you systematically process all products.

Processing orders

Once all products have been picked, you can process the orders. This can be done in two ways:

Without bins

Gather all products in one central bin.

Scan any product from the bin (or manually select an order).

ShopLinkr automatically opens the correct order.

You immediately see which products belong to it.

The shipping label is automatically requested and printed (if connected via PrintNode).

Scan the next product and process all orders in this way.

Working with bins

Provide each bin with a unique barcode (to be generated within ShopLinkr).

During picking, ShopLinkr connects each order to a specific bin (e.g., bin A, B, C...).

You scan the product first, then the correct bin. This way, you ensure the product ends up in the right bin.

Place the bins at the packing table.

The packer scans a bin, and the correct order opens automatically.

Scan the products again and process the order.

Advantage: this extra check prevents errors and saves time and money.