View all blogs

11 juni 2024

A backorder can sometimes be a confusing concept. But don’t worry, I will explain everything to you. A backorder occurs when a product is not immediately in stock but is ordered by a customer. This can happen in various situations, for example when a particular item is very popular and is sold out.

Definition of a backorder

To understand this better, let’s first take a look at the definition of a backorder. A backorder refers to an order that has yet to be fulfilled because the desired product is not available in the warehouse at the time of ordering. Instead of canceling the order, it is placed in a queue until the product is back in stock.

The basics of backorders

Backorders are actually a normal part of business. They allow customers to order a desired product even if it is temporarily out of stock. This is especially useful if you need a specific item that is not readily available in other stores.

When you place a backorder, your order is recorded, and a date is set for when the product is expected to be back in stock. In the meantime, you can look forward to the fact that you will soon have the desired product in your hands.

Difference between backorder and out-of-stock

It is important to understand the difference between a backorder and a product that is "out-of-stock." If a product is "out-of-stock," it means that it is not available at all right now and there is no possibility to order it. In the case of a backorder, the product is temporarily out of stock, but you can still place an order and wait for it to become available again.

While a backorder can be a convenient option for customers, it also brings some challenges for businesses. Managing backorders requires careful planning and inventory management. Companies must ensure that they have enough stock to meet demand while also preventing unsold inventory from piling up.

To achieve this, businesses use advanced inventory management systems and forecasting tools to predict demand and order the right amount of products. Additionally, they have to consider external factors such as seasonal demand and shipping delays.

Managing backorders also requires good communication with customers. Companies must be transparent about expected delivery times and proactively communicate any delays. This helps maintain customer trust and keeps them informed about the status of their order.

The importance of backorder management

Effective backorder management is essential for the smooth operation of your business activities. It enables you to maintain customer relationships, ensure customer satisfaction, and strengthen your competitive position.

Benefits of effective backorder management

Effective backorder management can bring various benefits. Firstly, it allows your customers to order their desired products, even if they are not immediately in stock. This can set your business apart from the competition and encourage customers to continue ordering from you.

Moreover, backorders can also serve as a valuable source of information for your business. By analyzing which products often generate backorders, you can optimize your inventory management and ensure that you always have enough stock of the most popular products.

Risks of poor backorder management

On the other hand, if you have poor backorder management, it can lead to dissatisfied customers, missed sales opportunities, and even reputational damage for your business. Customers may become frustrated if they have to wait a long time for a backorder and decide to shop elsewhere. Therefore, it is essential to ensure that your backorder management is in good shape.

How backorders affect customer satisfaction

Backorders can significantly impact customer satisfaction. When a customer orders a product that is temporarily out of stock, it can cause some inconvenience. Therefore, it is important to proactively communicate with your customers and keep them informed about the status of their backorder.

Impact on customer relationships

A good customer relationship is based on trust and transparency. When you communicate openly and honestly about backorders and the expected delivery time, you can maintain your customers' trust. They appreciate that you take their order seriously and keep them informed about any delays.

The importance of communication in backorders

Communication is key to successful backorder management. Make sure to regularly send updates to customers who are waiting on a backorder. Give them an estimated delivery date and any updates if changes occur. This way, your customers feel engaged and informed, which will benefit customer satisfaction.

Techniques to reduce backorders

Although backorders might be inevitable, there are several techniques you can apply to reduce the number of backorders and thereby increase customer satisfaction.

Inventory management and backorders

Effective inventory management is vital to reducing the number of backorders. By accurately predicting demand and always having enough stock, you can prevent customers from having to place a backorder. Use technology and analyze historical sales data to manage your inventory levels accurately.

The use of technology in backorder prevention

Additionally, implementing technology can help you effectively prevent backorders. Automated inventory systems can assist you in tracking your inventory levels, forecasting demand, and placing timely orders with your suppliers. This reduces the risk of backorders and ensures that you always have stock of your most popular products.

Conclusion: navigating backorders

While backorders can sometimes be challenging, they are a normal part of business. Effective backorder management is crucial to ensure customer satisfaction and keep your business operations running smoothly. Communicate regularly with your customers, reduce the number of backorders through good inventory management, and utilize technology to streamline your backorder process.

Key points to remember

Backorders are orders that have yet to be fulfilled because the desired product is temporarily out of stock.

Communication is essential in backorders to maintain customer relationships.

Effective inventory management and technology can reduce the number of backorders.

Future considerations for backorder management

Stay updated on new technologies that can help you prevent backorders.

Monitor demand and adjust your inventory management strategies to increase customer satisfaction.

With these insights, you can better navigate backorders and ensure that your customer satisfaction remains high. Good luck!

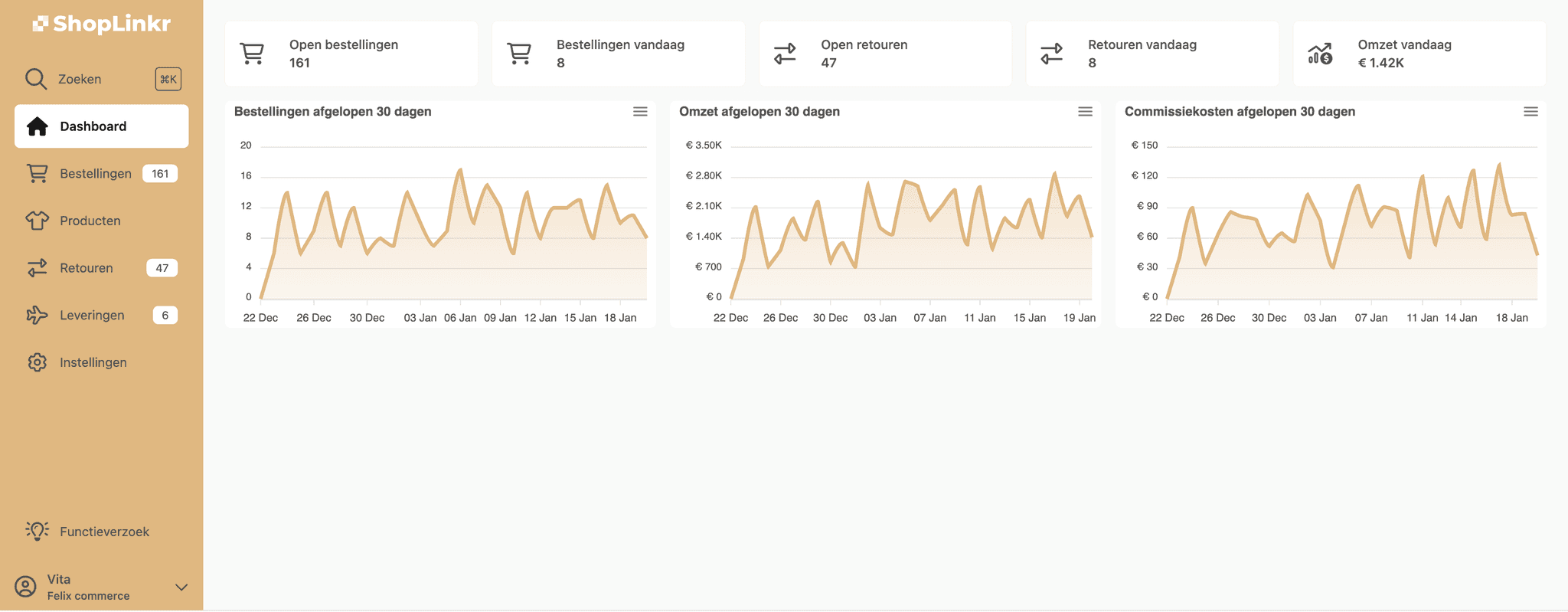

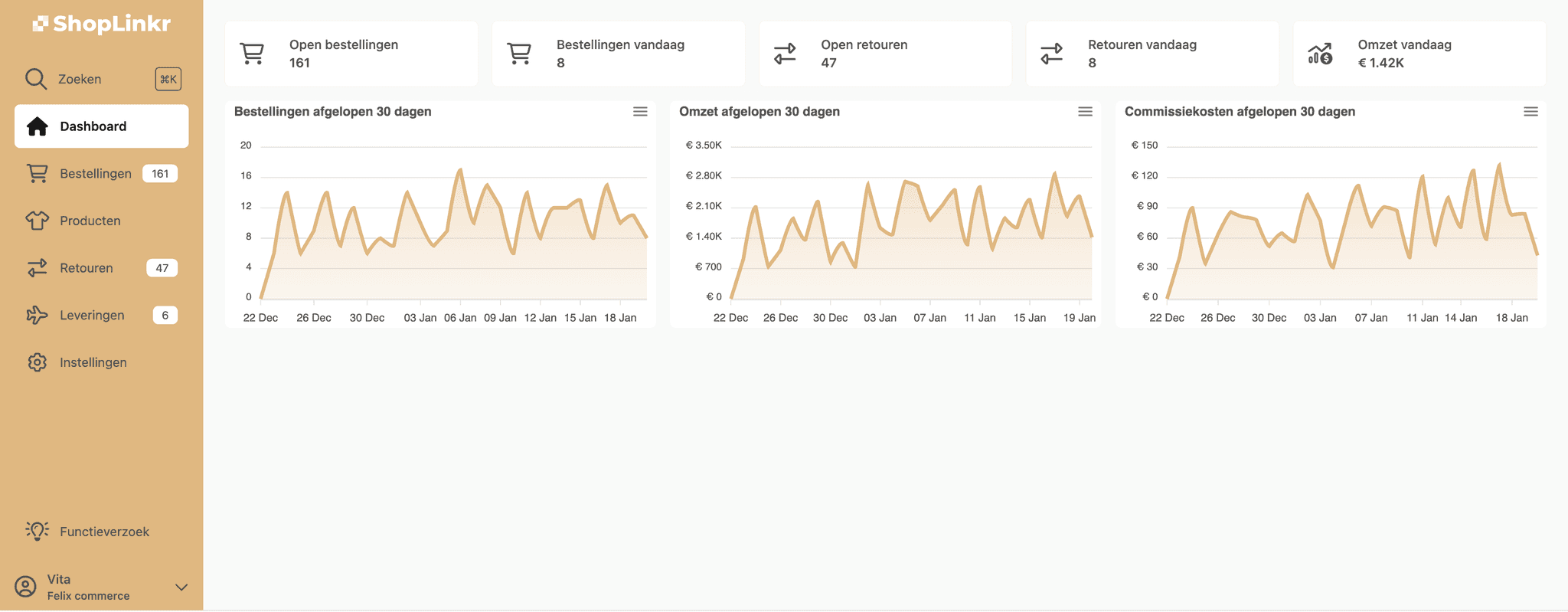

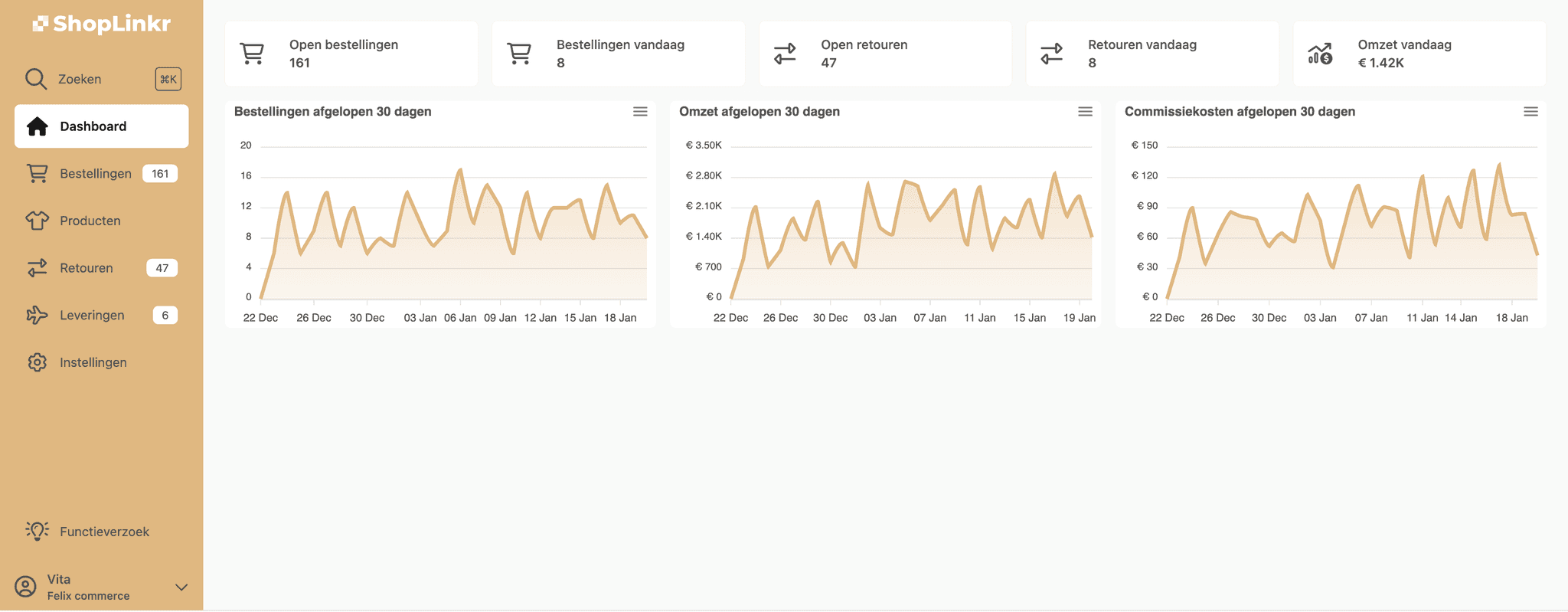

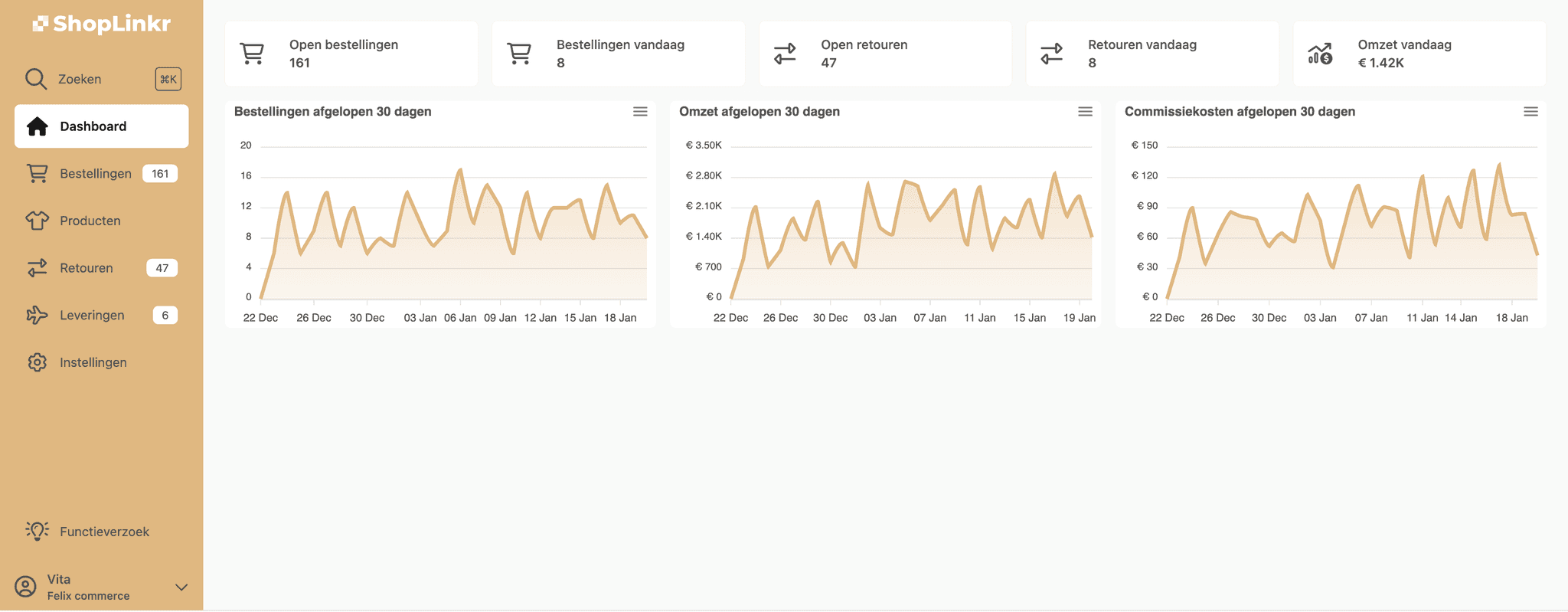

Are you tired of the hassle with backorders and want to take your inventory management to the next level? ShopLinkr helps you with easy order and inventory management for your web shop. With automatic inventory synchronization and a simple way to process orders, you can effortlessly keep everything tracked in one place. Plus, we partner with the most well-known and reliable companies. What are you waiting for? Try ShopLinkr now for 14 days free and say goodbye to backorder stress!

A backorder can sometimes be a confusing concept. But don’t worry, I will explain everything to you. A backorder occurs when a product is not immediately in stock but is ordered by a customer. This can happen in various situations, for example when a particular item is very popular and is sold out.

Definition of a backorder

To understand this better, let’s first take a look at the definition of a backorder. A backorder refers to an order that has yet to be fulfilled because the desired product is not available in the warehouse at the time of ordering. Instead of canceling the order, it is placed in a queue until the product is back in stock.

The basics of backorders

Backorders are actually a normal part of business. They allow customers to order a desired product even if it is temporarily out of stock. This is especially useful if you need a specific item that is not readily available in other stores.

When you place a backorder, your order is recorded, and a date is set for when the product is expected to be back in stock. In the meantime, you can look forward to the fact that you will soon have the desired product in your hands.

Difference between backorder and out-of-stock

It is important to understand the difference between a backorder and a product that is "out-of-stock." If a product is "out-of-stock," it means that it is not available at all right now and there is no possibility to order it. In the case of a backorder, the product is temporarily out of stock, but you can still place an order and wait for it to become available again.

While a backorder can be a convenient option for customers, it also brings some challenges for businesses. Managing backorders requires careful planning and inventory management. Companies must ensure that they have enough stock to meet demand while also preventing unsold inventory from piling up.

To achieve this, businesses use advanced inventory management systems and forecasting tools to predict demand and order the right amount of products. Additionally, they have to consider external factors such as seasonal demand and shipping delays.

Managing backorders also requires good communication with customers. Companies must be transparent about expected delivery times and proactively communicate any delays. This helps maintain customer trust and keeps them informed about the status of their order.

The importance of backorder management

Effective backorder management is essential for the smooth operation of your business activities. It enables you to maintain customer relationships, ensure customer satisfaction, and strengthen your competitive position.

Benefits of effective backorder management

Effective backorder management can bring various benefits. Firstly, it allows your customers to order their desired products, even if they are not immediately in stock. This can set your business apart from the competition and encourage customers to continue ordering from you.

Moreover, backorders can also serve as a valuable source of information for your business. By analyzing which products often generate backorders, you can optimize your inventory management and ensure that you always have enough stock of the most popular products.

Risks of poor backorder management

On the other hand, if you have poor backorder management, it can lead to dissatisfied customers, missed sales opportunities, and even reputational damage for your business. Customers may become frustrated if they have to wait a long time for a backorder and decide to shop elsewhere. Therefore, it is essential to ensure that your backorder management is in good shape.

How backorders affect customer satisfaction

Backorders can significantly impact customer satisfaction. When a customer orders a product that is temporarily out of stock, it can cause some inconvenience. Therefore, it is important to proactively communicate with your customers and keep them informed about the status of their backorder.

Impact on customer relationships

A good customer relationship is based on trust and transparency. When you communicate openly and honestly about backorders and the expected delivery time, you can maintain your customers' trust. They appreciate that you take their order seriously and keep them informed about any delays.

The importance of communication in backorders

Communication is key to successful backorder management. Make sure to regularly send updates to customers who are waiting on a backorder. Give them an estimated delivery date and any updates if changes occur. This way, your customers feel engaged and informed, which will benefit customer satisfaction.

Techniques to reduce backorders

Although backorders might be inevitable, there are several techniques you can apply to reduce the number of backorders and thereby increase customer satisfaction.

Inventory management and backorders

Effective inventory management is vital to reducing the number of backorders. By accurately predicting demand and always having enough stock, you can prevent customers from having to place a backorder. Use technology and analyze historical sales data to manage your inventory levels accurately.

The use of technology in backorder prevention

Additionally, implementing technology can help you effectively prevent backorders. Automated inventory systems can assist you in tracking your inventory levels, forecasting demand, and placing timely orders with your suppliers. This reduces the risk of backorders and ensures that you always have stock of your most popular products.

Conclusion: navigating backorders

While backorders can sometimes be challenging, they are a normal part of business. Effective backorder management is crucial to ensure customer satisfaction and keep your business operations running smoothly. Communicate regularly with your customers, reduce the number of backorders through good inventory management, and utilize technology to streamline your backorder process.

Key points to remember

Backorders are orders that have yet to be fulfilled because the desired product is temporarily out of stock.

Communication is essential in backorders to maintain customer relationships.

Effective inventory management and technology can reduce the number of backorders.

Future considerations for backorder management

Stay updated on new technologies that can help you prevent backorders.

Monitor demand and adjust your inventory management strategies to increase customer satisfaction.

With these insights, you can better navigate backorders and ensure that your customer satisfaction remains high. Good luck!

Are you tired of the hassle with backorders and want to take your inventory management to the next level? ShopLinkr helps you with easy order and inventory management for your web shop. With automatic inventory synchronization and a simple way to process orders, you can effortlessly keep everything tracked in one place. Plus, we partner with the most well-known and reliable companies. What are you waiting for? Try ShopLinkr now for 14 days free and say goodbye to backorder stress!

A backorder can sometimes be a confusing concept. But don’t worry, I will explain everything to you. A backorder occurs when a product is not immediately in stock but is ordered by a customer. This can happen in various situations, for example when a particular item is very popular and is sold out.

Definition of a backorder

To understand this better, let’s first take a look at the definition of a backorder. A backorder refers to an order that has yet to be fulfilled because the desired product is not available in the warehouse at the time of ordering. Instead of canceling the order, it is placed in a queue until the product is back in stock.

The basics of backorders

Backorders are actually a normal part of business. They allow customers to order a desired product even if it is temporarily out of stock. This is especially useful if you need a specific item that is not readily available in other stores.

When you place a backorder, your order is recorded, and a date is set for when the product is expected to be back in stock. In the meantime, you can look forward to the fact that you will soon have the desired product in your hands.

Difference between backorder and out-of-stock

It is important to understand the difference between a backorder and a product that is "out-of-stock." If a product is "out-of-stock," it means that it is not available at all right now and there is no possibility to order it. In the case of a backorder, the product is temporarily out of stock, but you can still place an order and wait for it to become available again.

While a backorder can be a convenient option for customers, it also brings some challenges for businesses. Managing backorders requires careful planning and inventory management. Companies must ensure that they have enough stock to meet demand while also preventing unsold inventory from piling up.

To achieve this, businesses use advanced inventory management systems and forecasting tools to predict demand and order the right amount of products. Additionally, they have to consider external factors such as seasonal demand and shipping delays.

Managing backorders also requires good communication with customers. Companies must be transparent about expected delivery times and proactively communicate any delays. This helps maintain customer trust and keeps them informed about the status of their order.

The importance of backorder management

Effective backorder management is essential for the smooth operation of your business activities. It enables you to maintain customer relationships, ensure customer satisfaction, and strengthen your competitive position.

Benefits of effective backorder management

Effective backorder management can bring various benefits. Firstly, it allows your customers to order their desired products, even if they are not immediately in stock. This can set your business apart from the competition and encourage customers to continue ordering from you.

Moreover, backorders can also serve as a valuable source of information for your business. By analyzing which products often generate backorders, you can optimize your inventory management and ensure that you always have enough stock of the most popular products.

Risks of poor backorder management

On the other hand, if you have poor backorder management, it can lead to dissatisfied customers, missed sales opportunities, and even reputational damage for your business. Customers may become frustrated if they have to wait a long time for a backorder and decide to shop elsewhere. Therefore, it is essential to ensure that your backorder management is in good shape.

How backorders affect customer satisfaction

Backorders can significantly impact customer satisfaction. When a customer orders a product that is temporarily out of stock, it can cause some inconvenience. Therefore, it is important to proactively communicate with your customers and keep them informed about the status of their backorder.

Impact on customer relationships

A good customer relationship is based on trust and transparency. When you communicate openly and honestly about backorders and the expected delivery time, you can maintain your customers' trust. They appreciate that you take their order seriously and keep them informed about any delays.

The importance of communication in backorders

Communication is key to successful backorder management. Make sure to regularly send updates to customers who are waiting on a backorder. Give them an estimated delivery date and any updates if changes occur. This way, your customers feel engaged and informed, which will benefit customer satisfaction.

Techniques to reduce backorders

Although backorders might be inevitable, there are several techniques you can apply to reduce the number of backorders and thereby increase customer satisfaction.

Inventory management and backorders

Effective inventory management is vital to reducing the number of backorders. By accurately predicting demand and always having enough stock, you can prevent customers from having to place a backorder. Use technology and analyze historical sales data to manage your inventory levels accurately.

The use of technology in backorder prevention

Additionally, implementing technology can help you effectively prevent backorders. Automated inventory systems can assist you in tracking your inventory levels, forecasting demand, and placing timely orders with your suppliers. This reduces the risk of backorders and ensures that you always have stock of your most popular products.

Conclusion: navigating backorders

While backorders can sometimes be challenging, they are a normal part of business. Effective backorder management is crucial to ensure customer satisfaction and keep your business operations running smoothly. Communicate regularly with your customers, reduce the number of backorders through good inventory management, and utilize technology to streamline your backorder process.

Key points to remember

Backorders are orders that have yet to be fulfilled because the desired product is temporarily out of stock.

Communication is essential in backorders to maintain customer relationships.

Effective inventory management and technology can reduce the number of backorders.

Future considerations for backorder management

Stay updated on new technologies that can help you prevent backorders.

Monitor demand and adjust your inventory management strategies to increase customer satisfaction.

With these insights, you can better navigate backorders and ensure that your customer satisfaction remains high. Good luck!

Are you tired of the hassle with backorders and want to take your inventory management to the next level? ShopLinkr helps you with easy order and inventory management for your web shop. With automatic inventory synchronization and a simple way to process orders, you can effortlessly keep everything tracked in one place. Plus, we partner with the most well-known and reliable companies. What are you waiting for? Try ShopLinkr now for 14 days free and say goodbye to backorder stress!

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date