The importance of effective inventory management

In the world of businesses and trade, inventory management is a crucial part of success.

The importance of effective inventory management

In the world of businesses and trade, inventory management is a crucial part of success.

The importance of effective inventory management

In the world of businesses and trade, inventory management is a crucial part of success.

The importance of effective inventory management

In the world of businesses and trade, inventory management is a crucial part of success.

View all blogs

18 mei 2024

In the world of businesses and trade, inventory management is a crucial component of success. Proper inventory management can increase efficiency, improve customer satisfaction, and reduce costs. On the other hand, poor inventory management can lead to delays, loss of sales, and dissatisfied customers. Therefore, it is important to understand and implement effective inventory management.

What is inventory management?

Inventory management refers to the process of planning, organizing, and controlling the inventory of products or materials that a company has in stock. It involves determining the right amount of inventory, timely ordering of new stock, and ensuring optimal storage and distribution of inventory. Effective inventory management means that inventory levels are balanced so that there is enough stock to meet demand without excessive inventory costs.

The basic principles of inventory management

To implement effective inventory management, it is important to understand the basic principles. One of the basic principles is the ABC analysis, where the inventory is categorized into three groups based on its value. The A category includes the most valuable inventory, while the C category includes the least valuable inventory. This helps companies focus their efforts and resources on the most valuable inventory while paying less attention to the less valuable inventory.

Another important factor is lead time, which is the time it takes to receive new stock after an order has been placed. Calculating the right lead time is essential to avoid shortages or surpluses. By accurately estimating lead times, companies can ensure that they receive new stock on time and that there are no interruptions in supply.

Different types of inventory management

There are several approaches to inventory management that companies can use, depending on their needs and business model. A common method is Just-in-Time (JIT) inventory management, where stock is ordered only when needed to minimize waste. This can help save costs, as companies do not need to store large quantities of inventory. Additionally, JIT inventory management can improve efficiency by reducing lead times and increasing productivity.

Another method is Economic Order Quantity (EOQ) inventory management, which calculates the optimal order quantity to minimize total costs. This method takes into account factors such as product demand, ordering and storage costs, and shortage costs. By calculating the optimal order quantity, companies can reduce their inventory costs while meeting demand.

It is important for businesses to evaluate the different methods and choose the best approach based on their specific situation. By applying effective inventory management, companies can improve operational efficiency, save costs, and increase customer satisfaction.

The importance of effective inventory management

Effective inventory management has many benefits for a company. It can increase efficiency by ensuring that there is enough stock to meet demand, but not too much, thereby preventing unnecessary costs. Additionally, effective inventory management can improve customer satisfaction. Customers will be happy if they receive their products on time and if there are no shortages. This can lead to repeat purchases and positive word-of-mouth advertising.

How effective inventory management increases efficiency

Effective inventory management can increase efficiency by reducing unnecessary costs and delays. By managing inventory levels properly, a company can reduce storage costs and free up space in the warehouse. Timely ordering of stock and avoiding shortages can also ensure that the production process runs smoothly without delays. This results in more efficient operations and lower costs.

Moreover, effective inventory management can also improve the quality of the production process. By having the right amount of stock available at the right time, a company can optimize production planning and reduce lead times. This ensures faster delivery of products to customers and reduces the chance of delivery delays.

The effect of inventory management on customer satisfaction

Customer satisfaction is essential for the success of a company. Effective inventory management can ensure that customers receive their products on time, which increases their satisfaction. Additionally, avoiding shortages can prevent customers from having to look for alternative suppliers, strengthening their relationship with the company. By ensuring consistent and reliable delivery, a company can gain and maintain customer trust.

Furthermore, effective inventory management can also improve customer service. With good inventory planning, companies can respond more quickly to customer inquiries and orders. This results in faster order processing and better communication with customers. Efficient inventory management also ensures that customers always have access to the products they need, preventing disappointment due to a lack of availability.

Challenges in inventory management

While effective inventory management is crucial, there are also challenges that companies may face. It is important to understand these challenges and find appropriate solutions.

Inventory management is a critical component of a company's success, whether it involves a small shop or a large multinational. Managing the right amount of inventory at the right time is essential to keep customers satisfied and minimize operational costs. Additionally, effective inventory management can also lead to improved cash flow and higher profitability.

Common problems in inventory management

One of the common problems in inventory management is excess inventory. This can lead to high storage costs and obsolete stock. Additionally, insufficient inventory can lead to shortages and loss of sales. It is also important to consider seasonal demand and trends to ensure that there is sufficient stock available during peak periods. Identifying and addressing these issues can help maintain healthy inventory management.

Another important aspect of inventory management is minimizing shrinkage. Shrinkage refers to products that are lost due to spoilage, theft, or damage. Through effective inventory rotation, security systems, and quality controls, companies can reduce shrinkage and increase their profitability.

How to address these challenges

To tackle the challenges of inventory management, companies can utilize techniques and strategies. Implementing an automated inventory management system can assist in tracking inventory levels and forecasting demand. Additionally, collaborating with suppliers and sharing information can help prevent shortages or surpluses. Regularly evaluating and adjusting inventory management processes is also vital to respond to changing conditions.

Technology and inventory management

Technology plays an increasingly important role in inventory management. The use of technology can simplify management and enable efficiency improvements.

The use of technology in inventory management

Technologies such as barcode scanners, RFID tags, and inventory management software make it possible to accurately track inventory levels and monitor stock movements. This makes management more efficient and helps reduce human error. Moreover, technology can aid in forecasting demand and optimizing order quantities. It is important for companies to stay updated with new technological developments and invest in suitable systems.

The future of inventory management and technology

The future of inventory management is expected to be increasingly influenced by technology. The rise of artificial intelligence and machine learning can, for example, assist in demand forecasting and optimizing inventory levels. Furthermore, connectivity and digital systems will enable real-time inventory information to be collected and shared. Companies investing in new technologies will create a competitive advantage and further improve their inventory management.

In addition to the mentioned technologies, other emerging trends will shape the future of inventory management. One of these trends is the use of drones in warehouses for conducting inventories and moving stock. Drones can operate more efficiently and quickly than human employees, potentially reducing operational costs and increasing the speed of stock movements.

Another emerging technology that could have a significant impact on inventory management is blockchain. Blockchain can be used to create a decentralized and secure system for tracking inventory movements and transactions. This can give companies more transparency and traceability in their supply chain, helping to prevent fraud and enhance overall inventory management efficiency.

Conclusion: the value of effective inventory management

Effective inventory management is vital for businesses. It helps to reduce costs, increase efficiency, and improve customer satisfaction. By understanding the basic principles of inventory management, applying various approaches, and utilizing technology, companies can optimize their inventory management and gain a competitive edge.

Summary of the key points

To effectively implement inventory management, it is important to understand the basic principles such as ABC analysis and lead time. Various approaches such as Just-in-Time and Economic Order Quantity can be applied based on the company’s needs. Challenges in inventory management, such as excess inventory and shortages, can be addressed using techniques and strategies, as well as the use of technology. The future of inventory management will be greatly influenced by technological developments, and companies must invest in suitable systems to stay competitive.

The importance of continuous improvement in inventory management

Effective inventory management is an ongoing process. Companies must continuously evaluate and improve their inventory management processes to respond to changing conditions, demand patterns, and technological developments. By striving for continuous improvement, companies can elevate their inventory management to a higher level and lay a solid foundation for long-term success.

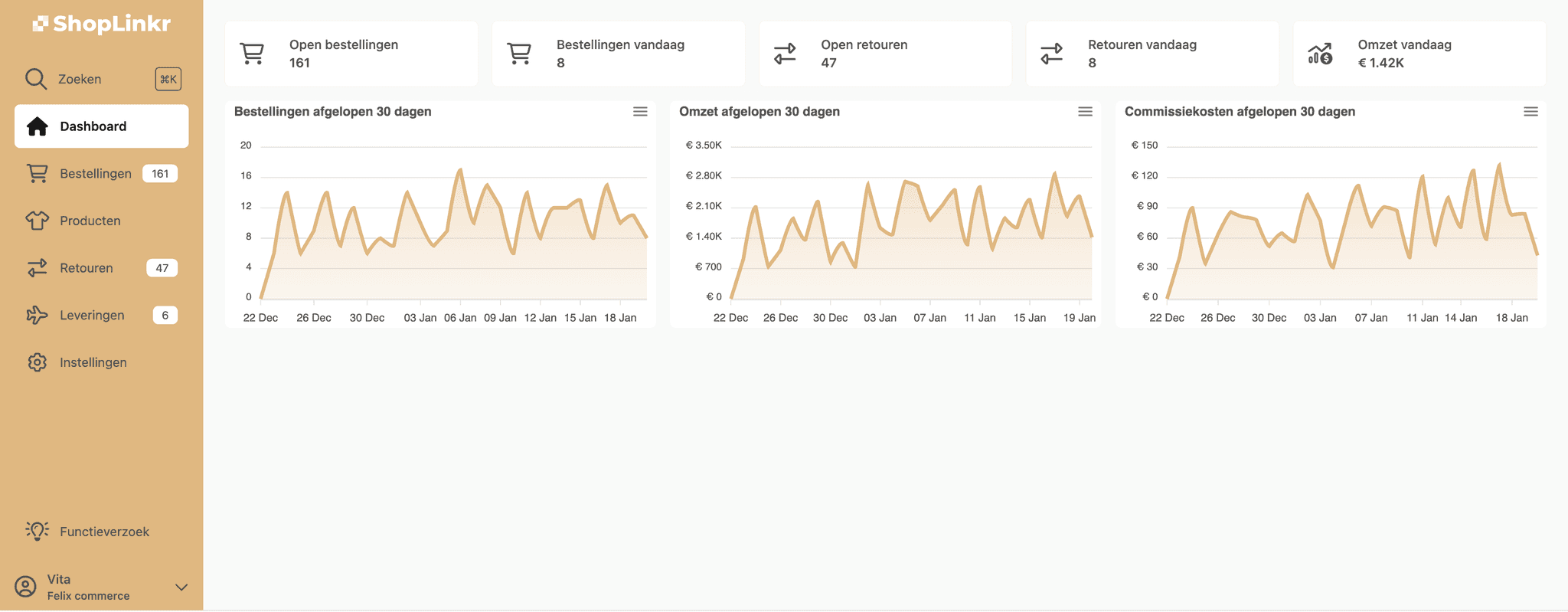

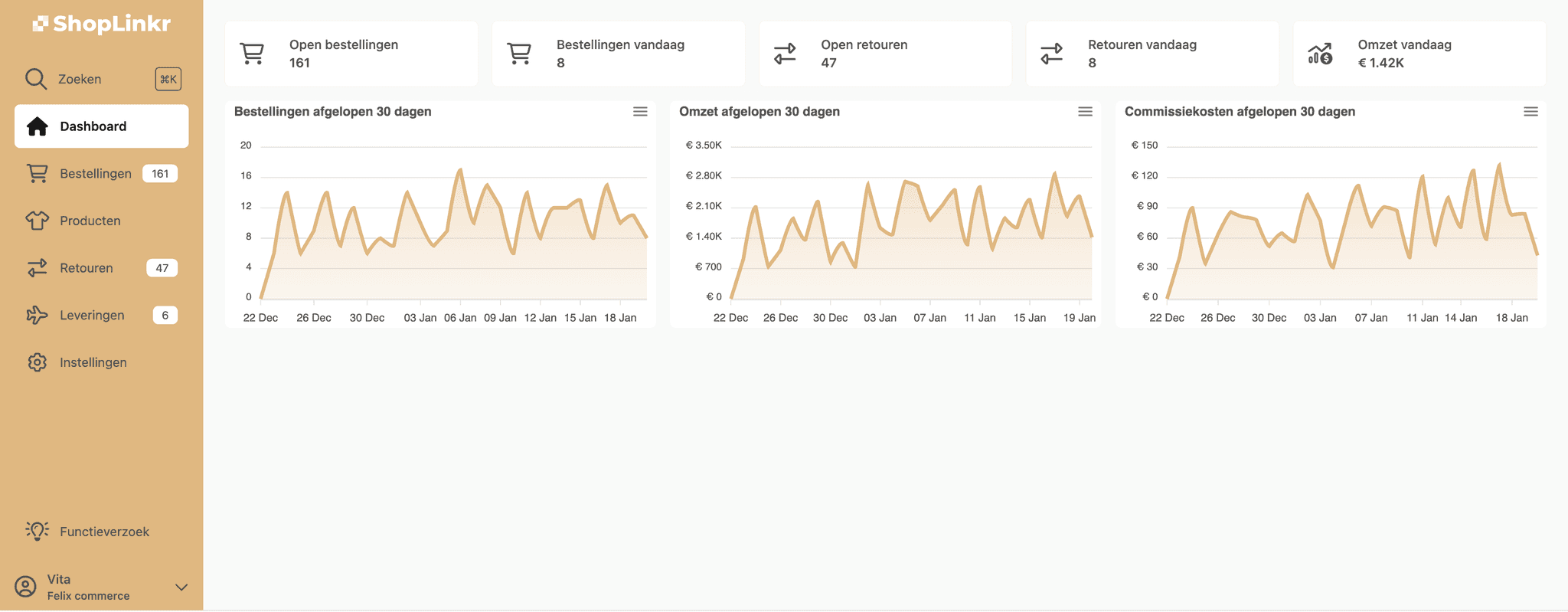

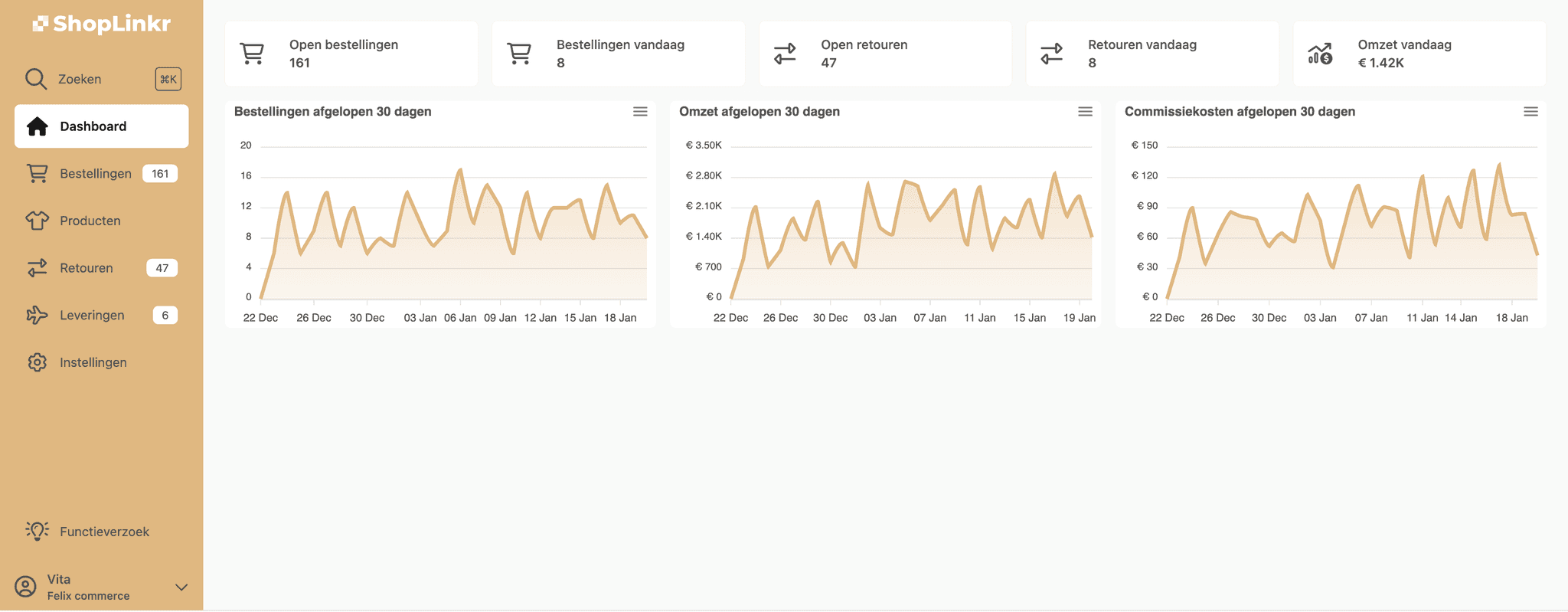

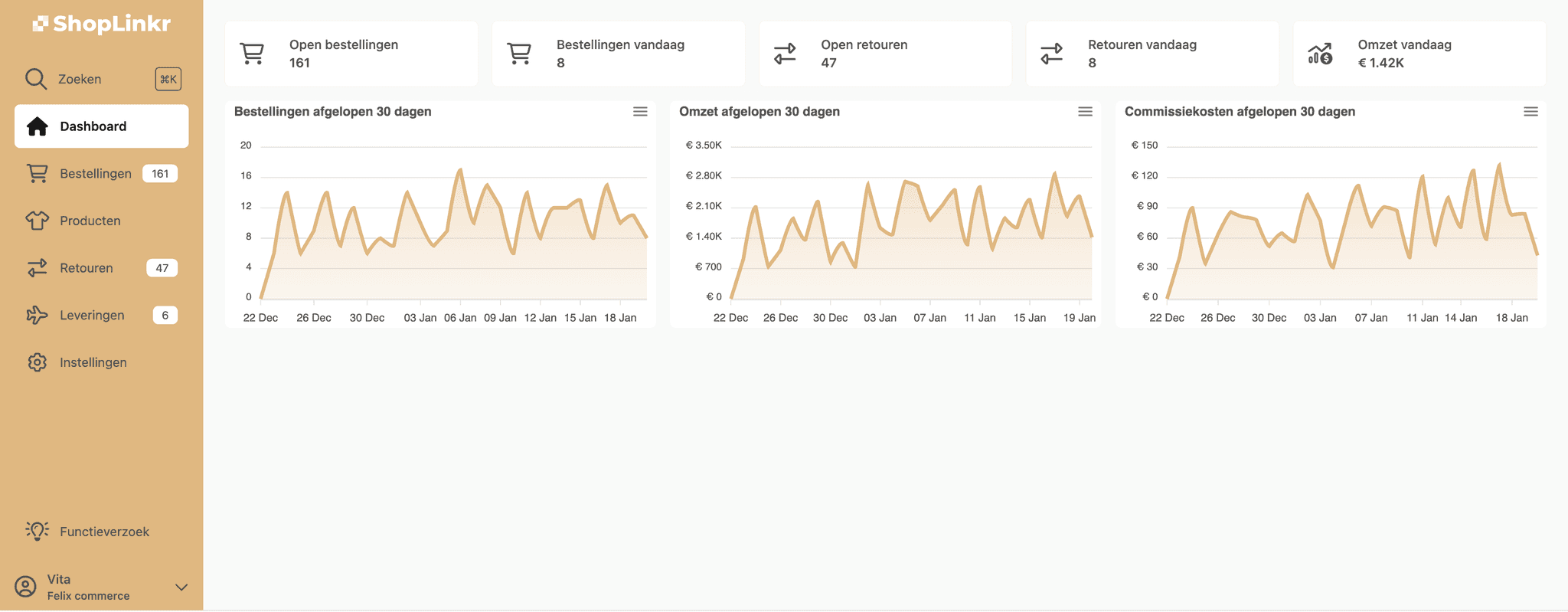

Are you ready to take your inventory management to the next level with the efficiency and ease of ShopLinkr? Join the thousands of satisfied users who have already processed over 110,000 orders and manage your inventory and orders in one central place. Try ShopLinkr now for 14 days free and experience how easy it is to be fully set up in 15 minutes.

In the world of businesses and trade, inventory management is a crucial component of success. Proper inventory management can increase efficiency, improve customer satisfaction, and reduce costs. On the other hand, poor inventory management can lead to delays, loss of sales, and dissatisfied customers. Therefore, it is important to understand and implement effective inventory management.

What is inventory management?

Inventory management refers to the process of planning, organizing, and controlling the inventory of products or materials that a company has in stock. It involves determining the right amount of inventory, timely ordering of new stock, and ensuring optimal storage and distribution of inventory. Effective inventory management means that inventory levels are balanced so that there is enough stock to meet demand without excessive inventory costs.

The basic principles of inventory management

To implement effective inventory management, it is important to understand the basic principles. One of the basic principles is the ABC analysis, where the inventory is categorized into three groups based on its value. The A category includes the most valuable inventory, while the C category includes the least valuable inventory. This helps companies focus their efforts and resources on the most valuable inventory while paying less attention to the less valuable inventory.

Another important factor is lead time, which is the time it takes to receive new stock after an order has been placed. Calculating the right lead time is essential to avoid shortages or surpluses. By accurately estimating lead times, companies can ensure that they receive new stock on time and that there are no interruptions in supply.

Different types of inventory management

There are several approaches to inventory management that companies can use, depending on their needs and business model. A common method is Just-in-Time (JIT) inventory management, where stock is ordered only when needed to minimize waste. This can help save costs, as companies do not need to store large quantities of inventory. Additionally, JIT inventory management can improve efficiency by reducing lead times and increasing productivity.

Another method is Economic Order Quantity (EOQ) inventory management, which calculates the optimal order quantity to minimize total costs. This method takes into account factors such as product demand, ordering and storage costs, and shortage costs. By calculating the optimal order quantity, companies can reduce their inventory costs while meeting demand.

It is important for businesses to evaluate the different methods and choose the best approach based on their specific situation. By applying effective inventory management, companies can improve operational efficiency, save costs, and increase customer satisfaction.

The importance of effective inventory management

Effective inventory management has many benefits for a company. It can increase efficiency by ensuring that there is enough stock to meet demand, but not too much, thereby preventing unnecessary costs. Additionally, effective inventory management can improve customer satisfaction. Customers will be happy if they receive their products on time and if there are no shortages. This can lead to repeat purchases and positive word-of-mouth advertising.

How effective inventory management increases efficiency

Effective inventory management can increase efficiency by reducing unnecessary costs and delays. By managing inventory levels properly, a company can reduce storage costs and free up space in the warehouse. Timely ordering of stock and avoiding shortages can also ensure that the production process runs smoothly without delays. This results in more efficient operations and lower costs.

Moreover, effective inventory management can also improve the quality of the production process. By having the right amount of stock available at the right time, a company can optimize production planning and reduce lead times. This ensures faster delivery of products to customers and reduces the chance of delivery delays.

The effect of inventory management on customer satisfaction

Customer satisfaction is essential for the success of a company. Effective inventory management can ensure that customers receive their products on time, which increases their satisfaction. Additionally, avoiding shortages can prevent customers from having to look for alternative suppliers, strengthening their relationship with the company. By ensuring consistent and reliable delivery, a company can gain and maintain customer trust.

Furthermore, effective inventory management can also improve customer service. With good inventory planning, companies can respond more quickly to customer inquiries and orders. This results in faster order processing and better communication with customers. Efficient inventory management also ensures that customers always have access to the products they need, preventing disappointment due to a lack of availability.

Challenges in inventory management

While effective inventory management is crucial, there are also challenges that companies may face. It is important to understand these challenges and find appropriate solutions.

Inventory management is a critical component of a company's success, whether it involves a small shop or a large multinational. Managing the right amount of inventory at the right time is essential to keep customers satisfied and minimize operational costs. Additionally, effective inventory management can also lead to improved cash flow and higher profitability.

Common problems in inventory management

One of the common problems in inventory management is excess inventory. This can lead to high storage costs and obsolete stock. Additionally, insufficient inventory can lead to shortages and loss of sales. It is also important to consider seasonal demand and trends to ensure that there is sufficient stock available during peak periods. Identifying and addressing these issues can help maintain healthy inventory management.

Another important aspect of inventory management is minimizing shrinkage. Shrinkage refers to products that are lost due to spoilage, theft, or damage. Through effective inventory rotation, security systems, and quality controls, companies can reduce shrinkage and increase their profitability.

How to address these challenges

To tackle the challenges of inventory management, companies can utilize techniques and strategies. Implementing an automated inventory management system can assist in tracking inventory levels and forecasting demand. Additionally, collaborating with suppliers and sharing information can help prevent shortages or surpluses. Regularly evaluating and adjusting inventory management processes is also vital to respond to changing conditions.

Technology and inventory management

Technology plays an increasingly important role in inventory management. The use of technology can simplify management and enable efficiency improvements.

The use of technology in inventory management

Technologies such as barcode scanners, RFID tags, and inventory management software make it possible to accurately track inventory levels and monitor stock movements. This makes management more efficient and helps reduce human error. Moreover, technology can aid in forecasting demand and optimizing order quantities. It is important for companies to stay updated with new technological developments and invest in suitable systems.

The future of inventory management and technology

The future of inventory management is expected to be increasingly influenced by technology. The rise of artificial intelligence and machine learning can, for example, assist in demand forecasting and optimizing inventory levels. Furthermore, connectivity and digital systems will enable real-time inventory information to be collected and shared. Companies investing in new technologies will create a competitive advantage and further improve their inventory management.

In addition to the mentioned technologies, other emerging trends will shape the future of inventory management. One of these trends is the use of drones in warehouses for conducting inventories and moving stock. Drones can operate more efficiently and quickly than human employees, potentially reducing operational costs and increasing the speed of stock movements.

Another emerging technology that could have a significant impact on inventory management is blockchain. Blockchain can be used to create a decentralized and secure system for tracking inventory movements and transactions. This can give companies more transparency and traceability in their supply chain, helping to prevent fraud and enhance overall inventory management efficiency.

Conclusion: the value of effective inventory management

Effective inventory management is vital for businesses. It helps to reduce costs, increase efficiency, and improve customer satisfaction. By understanding the basic principles of inventory management, applying various approaches, and utilizing technology, companies can optimize their inventory management and gain a competitive edge.

Summary of the key points

To effectively implement inventory management, it is important to understand the basic principles such as ABC analysis and lead time. Various approaches such as Just-in-Time and Economic Order Quantity can be applied based on the company’s needs. Challenges in inventory management, such as excess inventory and shortages, can be addressed using techniques and strategies, as well as the use of technology. The future of inventory management will be greatly influenced by technological developments, and companies must invest in suitable systems to stay competitive.

The importance of continuous improvement in inventory management

Effective inventory management is an ongoing process. Companies must continuously evaluate and improve their inventory management processes to respond to changing conditions, demand patterns, and technological developments. By striving for continuous improvement, companies can elevate their inventory management to a higher level and lay a solid foundation for long-term success.

Are you ready to take your inventory management to the next level with the efficiency and ease of ShopLinkr? Join the thousands of satisfied users who have already processed over 110,000 orders and manage your inventory and orders in one central place. Try ShopLinkr now for 14 days free and experience how easy it is to be fully set up in 15 minutes.

In the world of businesses and trade, inventory management is a crucial component of success. Proper inventory management can increase efficiency, improve customer satisfaction, and reduce costs. On the other hand, poor inventory management can lead to delays, loss of sales, and dissatisfied customers. Therefore, it is important to understand and implement effective inventory management.

What is inventory management?

Inventory management refers to the process of planning, organizing, and controlling the inventory of products or materials that a company has in stock. It involves determining the right amount of inventory, timely ordering of new stock, and ensuring optimal storage and distribution of inventory. Effective inventory management means that inventory levels are balanced so that there is enough stock to meet demand without excessive inventory costs.

The basic principles of inventory management

To implement effective inventory management, it is important to understand the basic principles. One of the basic principles is the ABC analysis, where the inventory is categorized into three groups based on its value. The A category includes the most valuable inventory, while the C category includes the least valuable inventory. This helps companies focus their efforts and resources on the most valuable inventory while paying less attention to the less valuable inventory.

Another important factor is lead time, which is the time it takes to receive new stock after an order has been placed. Calculating the right lead time is essential to avoid shortages or surpluses. By accurately estimating lead times, companies can ensure that they receive new stock on time and that there are no interruptions in supply.

Different types of inventory management

There are several approaches to inventory management that companies can use, depending on their needs and business model. A common method is Just-in-Time (JIT) inventory management, where stock is ordered only when needed to minimize waste. This can help save costs, as companies do not need to store large quantities of inventory. Additionally, JIT inventory management can improve efficiency by reducing lead times and increasing productivity.

Another method is Economic Order Quantity (EOQ) inventory management, which calculates the optimal order quantity to minimize total costs. This method takes into account factors such as product demand, ordering and storage costs, and shortage costs. By calculating the optimal order quantity, companies can reduce their inventory costs while meeting demand.

It is important for businesses to evaluate the different methods and choose the best approach based on their specific situation. By applying effective inventory management, companies can improve operational efficiency, save costs, and increase customer satisfaction.

The importance of effective inventory management

Effective inventory management has many benefits for a company. It can increase efficiency by ensuring that there is enough stock to meet demand, but not too much, thereby preventing unnecessary costs. Additionally, effective inventory management can improve customer satisfaction. Customers will be happy if they receive their products on time and if there are no shortages. This can lead to repeat purchases and positive word-of-mouth advertising.

How effective inventory management increases efficiency

Effective inventory management can increase efficiency by reducing unnecessary costs and delays. By managing inventory levels properly, a company can reduce storage costs and free up space in the warehouse. Timely ordering of stock and avoiding shortages can also ensure that the production process runs smoothly without delays. This results in more efficient operations and lower costs.

Moreover, effective inventory management can also improve the quality of the production process. By having the right amount of stock available at the right time, a company can optimize production planning and reduce lead times. This ensures faster delivery of products to customers and reduces the chance of delivery delays.

The effect of inventory management on customer satisfaction

Customer satisfaction is essential for the success of a company. Effective inventory management can ensure that customers receive their products on time, which increases their satisfaction. Additionally, avoiding shortages can prevent customers from having to look for alternative suppliers, strengthening their relationship with the company. By ensuring consistent and reliable delivery, a company can gain and maintain customer trust.

Furthermore, effective inventory management can also improve customer service. With good inventory planning, companies can respond more quickly to customer inquiries and orders. This results in faster order processing and better communication with customers. Efficient inventory management also ensures that customers always have access to the products they need, preventing disappointment due to a lack of availability.

Challenges in inventory management

While effective inventory management is crucial, there are also challenges that companies may face. It is important to understand these challenges and find appropriate solutions.

Inventory management is a critical component of a company's success, whether it involves a small shop or a large multinational. Managing the right amount of inventory at the right time is essential to keep customers satisfied and minimize operational costs. Additionally, effective inventory management can also lead to improved cash flow and higher profitability.

Common problems in inventory management

One of the common problems in inventory management is excess inventory. This can lead to high storage costs and obsolete stock. Additionally, insufficient inventory can lead to shortages and loss of sales. It is also important to consider seasonal demand and trends to ensure that there is sufficient stock available during peak periods. Identifying and addressing these issues can help maintain healthy inventory management.

Another important aspect of inventory management is minimizing shrinkage. Shrinkage refers to products that are lost due to spoilage, theft, or damage. Through effective inventory rotation, security systems, and quality controls, companies can reduce shrinkage and increase their profitability.

How to address these challenges

To tackle the challenges of inventory management, companies can utilize techniques and strategies. Implementing an automated inventory management system can assist in tracking inventory levels and forecasting demand. Additionally, collaborating with suppliers and sharing information can help prevent shortages or surpluses. Regularly evaluating and adjusting inventory management processes is also vital to respond to changing conditions.

Technology and inventory management

Technology plays an increasingly important role in inventory management. The use of technology can simplify management and enable efficiency improvements.

The use of technology in inventory management

Technologies such as barcode scanners, RFID tags, and inventory management software make it possible to accurately track inventory levels and monitor stock movements. This makes management more efficient and helps reduce human error. Moreover, technology can aid in forecasting demand and optimizing order quantities. It is important for companies to stay updated with new technological developments and invest in suitable systems.

The future of inventory management and technology

The future of inventory management is expected to be increasingly influenced by technology. The rise of artificial intelligence and machine learning can, for example, assist in demand forecasting and optimizing inventory levels. Furthermore, connectivity and digital systems will enable real-time inventory information to be collected and shared. Companies investing in new technologies will create a competitive advantage and further improve their inventory management.

In addition to the mentioned technologies, other emerging trends will shape the future of inventory management. One of these trends is the use of drones in warehouses for conducting inventories and moving stock. Drones can operate more efficiently and quickly than human employees, potentially reducing operational costs and increasing the speed of stock movements.

Another emerging technology that could have a significant impact on inventory management is blockchain. Blockchain can be used to create a decentralized and secure system for tracking inventory movements and transactions. This can give companies more transparency and traceability in their supply chain, helping to prevent fraud and enhance overall inventory management efficiency.

Conclusion: the value of effective inventory management

Effective inventory management is vital for businesses. It helps to reduce costs, increase efficiency, and improve customer satisfaction. By understanding the basic principles of inventory management, applying various approaches, and utilizing technology, companies can optimize their inventory management and gain a competitive edge.

Summary of the key points

To effectively implement inventory management, it is important to understand the basic principles such as ABC analysis and lead time. Various approaches such as Just-in-Time and Economic Order Quantity can be applied based on the company’s needs. Challenges in inventory management, such as excess inventory and shortages, can be addressed using techniques and strategies, as well as the use of technology. The future of inventory management will be greatly influenced by technological developments, and companies must invest in suitable systems to stay competitive.

The importance of continuous improvement in inventory management

Effective inventory management is an ongoing process. Companies must continuously evaluate and improve their inventory management processes to respond to changing conditions, demand patterns, and technological developments. By striving for continuous improvement, companies can elevate their inventory management to a higher level and lay a solid foundation for long-term success.

Are you ready to take your inventory management to the next level with the efficiency and ease of ShopLinkr? Join the thousands of satisfied users who have already processed over 110,000 orders and manage your inventory and orders in one central place. Try ShopLinkr now for 14 days free and experience how easy it is to be fully set up in 15 minutes.

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date