Effective inventory management in Excel: tips and tricks

Inventory management is an essential part of a successful business.

Effective inventory management in Excel: tips and tricks

Inventory management is an essential part of a successful business.

Effective inventory management in Excel: tips and tricks

Inventory management is an essential part of a successful business.

Effective inventory management in Excel: tips and tricks

Inventory management is an essential part of a successful business.

View all blogs

18 mei 2024

Inventory management is an essential part of a successful business. It allows you to keep track of the quantity of products you have in stock, so you always have enough inventory to meet the demand of your customers. But how can you do this effectively using Microsoft Excel? In this article, we will share some handy tips and tricks that will elevate your inventory management to the next level.

Understanding Inventory Management

Before we dive into specific Excel tips, it is important to have a good understanding of inventory management and why it is so crucial for a company. Effective inventory management ensures that you always have enough products in stock to meet customer demand while simultaneously minimizing the costs of holding inventory.

The Importance of Effective Inventory Management

Effective inventory management has several benefits for a business. First, it helps you avoid having too much inventory, which can lead to unnecessary costs such as storage fees and obsolete stock. Additionally, it allows you to prevent shortages, ensuring that your customers remain satisfied.

Fundamentals of Inventory Management

There are some fundamental principles you need to understand to effectively carry out inventory management in Excel. First, you need to have a clear picture of the demand for your products. It is important to keep track of sales figures and identify trends. You also need to be aware of your suppliers' lead times so that you can anticipate potential delays. Finally, you must ensure a good balance between inventory costs and customer satisfaction.

In addition to managing physical inventory, it is also essential to pay attention to optimizing inventory turnover. Inventory turnover refers to how quickly products are sold and replaced. By improving inventory turnover, you can enhance your business's cash flow and make room for new products. This can be achieved, for instance, by strategically placing seasonal products and planning promotions to boost sales.

Another important aspect of effective inventory management is implementing a just-in-time (JIT) inventory management system. With a JIT system, products are ordered and received only when they are needed, minimizing the costs of excess inventory. This requires close collaboration with suppliers and a well-organized logistics process to ensure that products arrive on time to meet the demand.

Excel as a Tool for Inventory Management

Excel is a powerful tool that you can use for inventory management. It offers various features and capabilities that allow you to manage your inventory efficiently. Let's take a look at why Excel is such a helpful tool for inventory management.

Why Use Excel for Inventory Management

Excel is a widely used program known for its versatility and ease of use. It enables you to organize and analyze data in a clear manner, which is particularly useful when managing your inventory. Additionally, you can utilize various formulas and functions in Excel to perform calculations and gain insight into your inventory levels.

The Benefits of Excel in Inventory Management

Excel offers several advantages for inventory management. First, you can easily keep an overview of your inventory with Excel. You can create columns for product names, stock quantities, purchase and sale prices, and more. Additionally, you can create graphs and charts using Excel to visualize trends and patterns in your inventory. This can help you make better-informed decisions.

Besides the mentioned benefits, Excel also offers the ability to set up automated alerts for specific inventory levels. By applying simple conditional formatting rules, you can set Excel to alert you when a product is running low or when a certain minimum level is reached. This way, you can take proactive measures to prevent shortages and keep your inventory in check.

Tips for Inventory Management in Excel

Now that we have a good understanding of inventory management and why Excel is a helpful tool, it's time to share some practical tips to improve your inventory management in Excel.

Setting Up Your Excel Inventory Management System

A good first step is to establish a structured Excel inventory management system. Create a worksheet with different columns for the product information you want to track. Utilize filters and sorting functions to quickly find the information you need. You can also use color codes to differentiate between product categories or priorities.

A useful addition to your Excel inventory management system is the use of dropdown menus for certain columns, such as suppliers or product categories. This helps prevent typographical errors and makes data entry more efficient. Don't forget to regularly back up your Excel file to prevent data loss.

Using Formulas and Functions for Inventory Management

One of the significant advantages of Excel is the ability to use formulas and functions to perform calculations. Use formulas to automatically update stock levels based on purchase and sales transactions. Also, use functions like SUM and AVERAGE to gain insight into the total value of your inventory and the average selling price.

In addition to standard Excel functions, you can also create custom formulas to perform specific calculations, such as determining the optimal order quantity based on demand and lead time. By customizing formulas, you can further optimize and streamline your inventory management.

Advanced Excel Tricks for Inventory Management

If you want to go beyond the basic functionalities of Excel, there are also some advanced tricks you can apply to optimize your inventory management.

In addition to using pivot tables and Excel macros, there are other advanced techniques you can apply to make your inventory management more efficient. One of these techniques is using advanced formulas and functions in Excel. By using complex formulas like VLOOKUP and IF functions, you can make Excel calculate and make decisions based on specific inventory data. This can be helpful in determining reorder levels or identifying slow-moving inventory.

Using Pivot Tables for Inventory Analysis

A pivot table is a powerful feature that allows you to summarize and analyze large amounts of data. You can use pivot tables to gain insight into your inventory levels, sales performance, and other key metrics. With just a few clicks, you can create various views and pivot based on the data you want to analyze.

Another handy application of pivot tables is visualizing your inventory data. By adding graphs and charts to your pivot table reports, you can quickly identify trends and patterns in your inventory data. This can help you make strategic decisions, such as optimizing your inventory levels or planning promotional activities.

Automating Inventory Management with Excel Macros

Excel macros are snippets of code you can write to automate certain tasks in Excel. With macros, you can automatically perform repetitive actions, such as updating stock levels. This not only saves you time but also minimizes the risk of errors. For example, you can create a macro that automatically updates your stock levels when you add new purchase or sales transactions.

An important aspect of working with Excel macros is understanding the programming language VBA (Visual Basic for Applications). By delving into VBA, you can write more complex and powerful macros that are specifically tailored to your inventory management processes. With VBA, you can create macros that import data from external sources, generate automated reports, or even interact with other software applications.

Common Pitfalls in Inventory Management with Excel

While Excel is a powerful tool for inventory management, there are also some pitfalls to watch out for.

In addition to known pitfalls, there are other aspects you need to consider when managing your inventory in Excel. For instance, it is essential to ensure a clear and consistent naming of your inventory items. This prevents confusion and errors during data entry. It is also advisable to use a separate tab or worksheet for each inventory category to maintain clarity and quickly find the information you need.

Common Mistakes and How to Avoid Them

A common mistake is forgetting to update stock levels after each purchase or sales transaction. It is important to regularly check this and ensure that your stock levels are always accurate. Another frequent mistake is relying solely on Excel as your only source of information. It is important to consult other sources and remain critical when making decisions based on Excel data.

Best Practices for Effective Inventory Management in Excel

To ensure that your inventory management in Excel remains effective, there are some best practices you can follow. Make regular backups of your Excel files to prevent data loss. Also, keep your formulas and functions up to date and ensure they work correctly. Finally, it is important to regularly evaluate and optimize your inventory management process based on new insights and changes in your business.

An additional tip is to use color codes in your Excel sheet to quickly gain insight into the status of your inventory. For example, you could use green for items that are well stocked, yellow for items that are running low, and red for items that need to be reordered urgently. These visual indicators help you take quick action and prevent issues.

Conclusion

Inventory management is a crucial part of a successful business, and Excel can be a valuable tool for efficiently managing your inventory. With Excel, you can keep a clear overview of your inventory, automate calculations, and gain insights into your inventory trends. By applying some handy tips and tricks, you can elevate your inventory management and minimize costs while maximizing customer satisfaction.

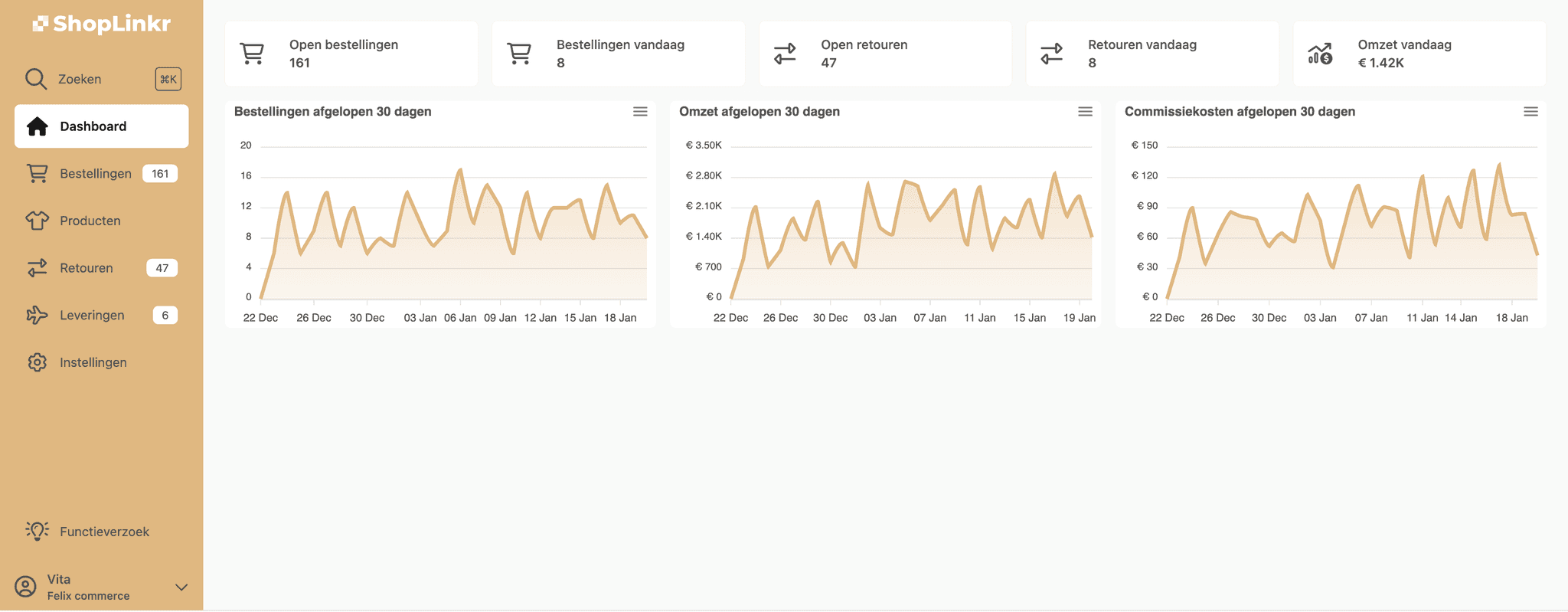

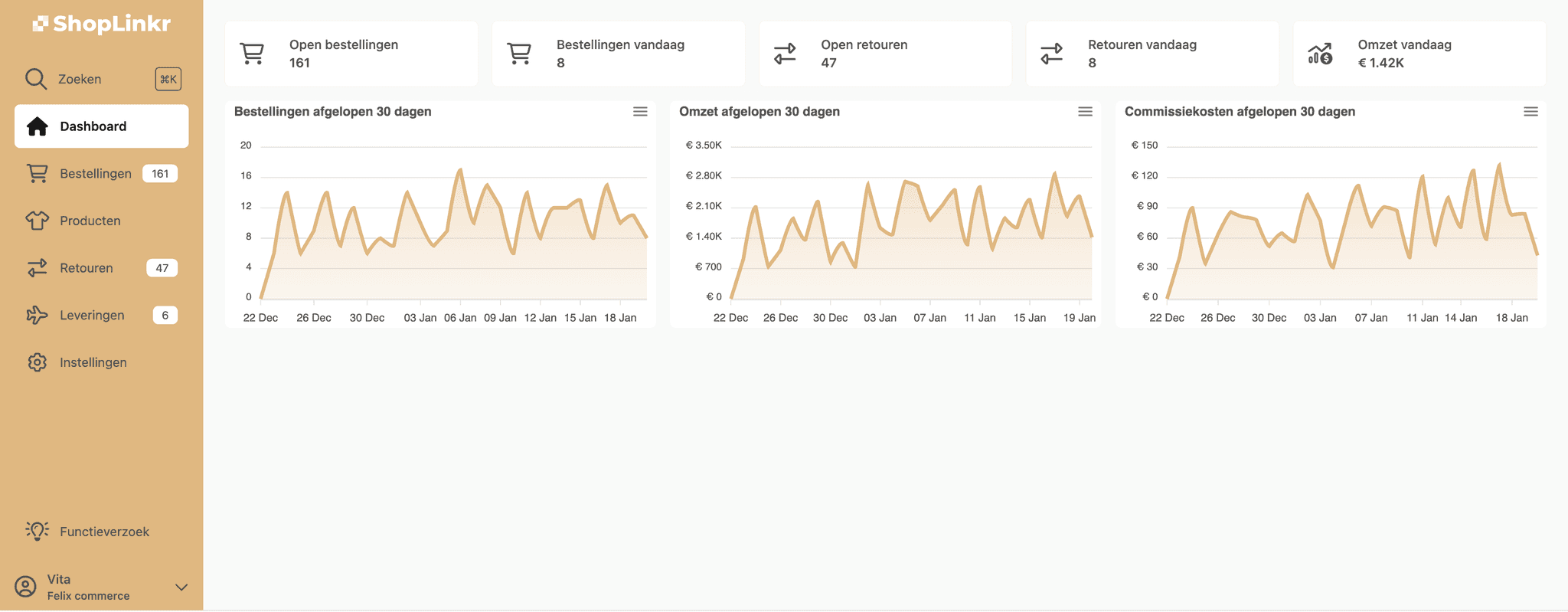

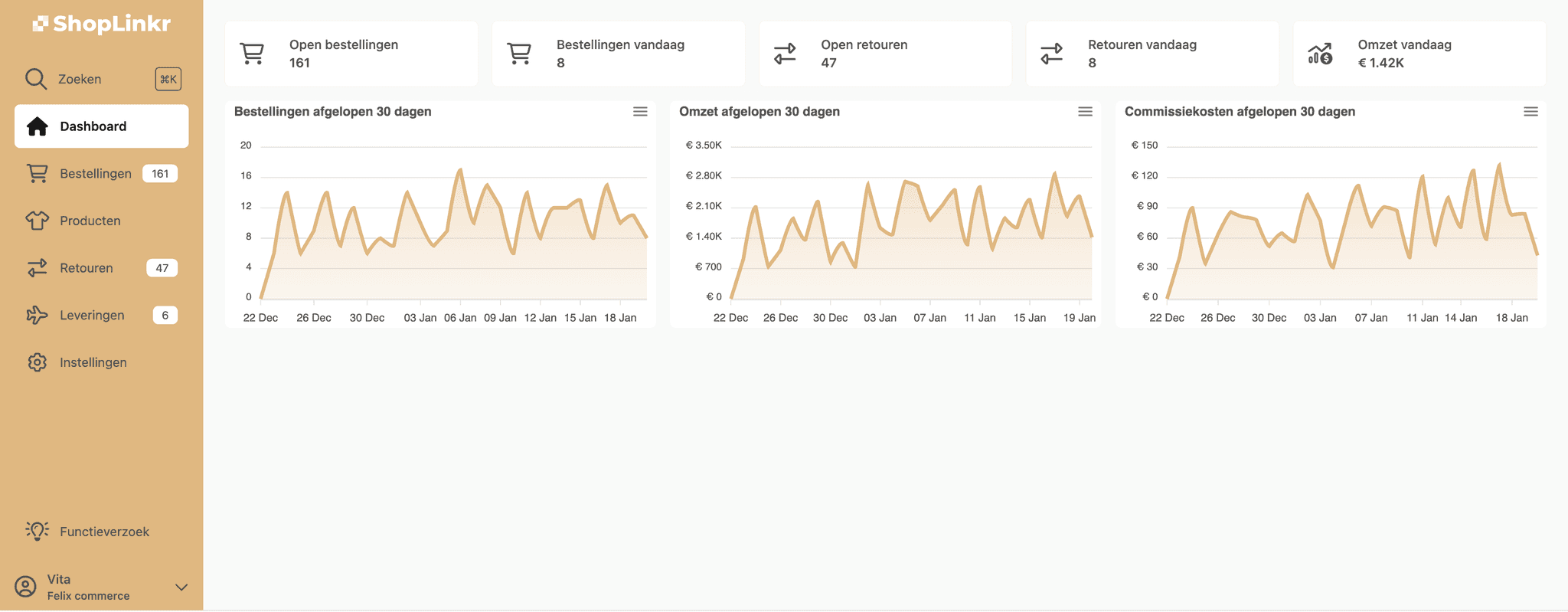

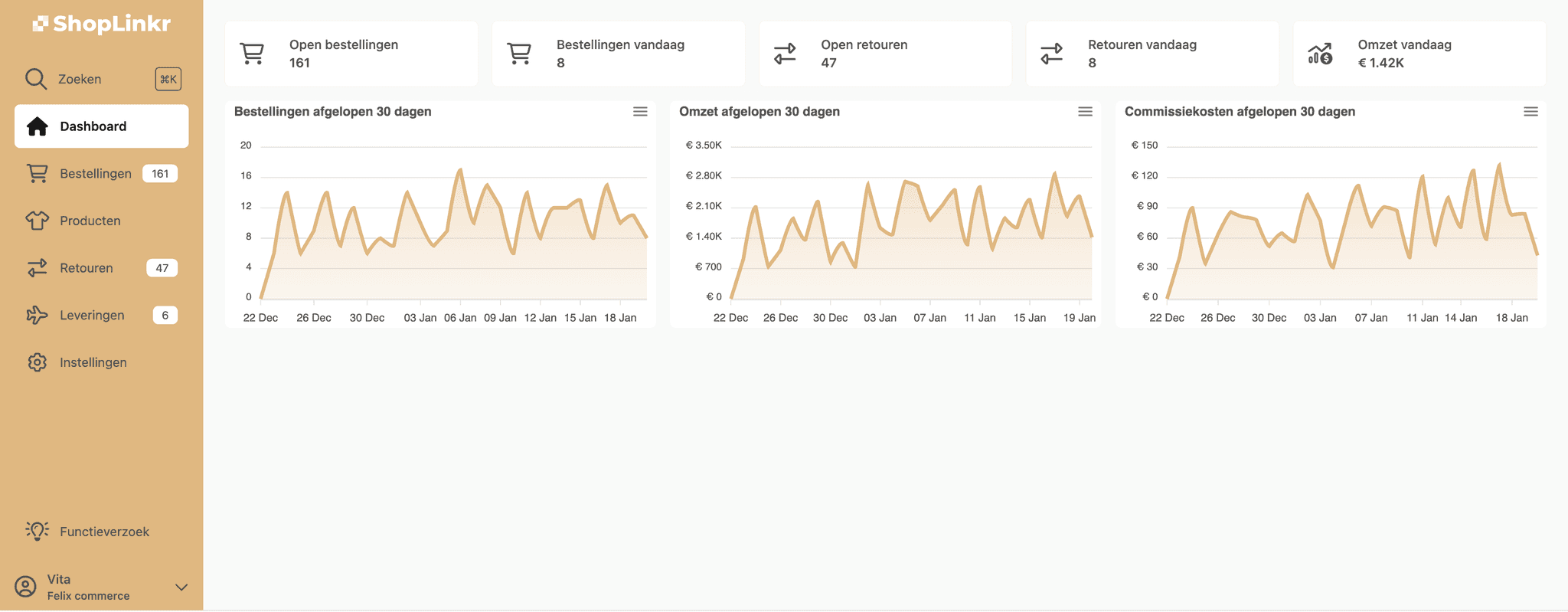

Are you ready to take your inventory management to the next level with the efficiency and convenience of ShopLinkr? Join the thousands of satisfied users who have already processed over 110,000 orders and manage your inventory and orders in one central place. Try ShopLinkr now for 14 days free and experience how easy it is to be fully set up in just 15 minutes.

Inventory management is an essential part of a successful business. It allows you to keep track of the quantity of products you have in stock, so you always have enough inventory to meet the demand of your customers. But how can you do this effectively using Microsoft Excel? In this article, we will share some handy tips and tricks that will elevate your inventory management to the next level.

Understanding Inventory Management

Before we dive into specific Excel tips, it is important to have a good understanding of inventory management and why it is so crucial for a company. Effective inventory management ensures that you always have enough products in stock to meet customer demand while simultaneously minimizing the costs of holding inventory.

The Importance of Effective Inventory Management

Effective inventory management has several benefits for a business. First, it helps you avoid having too much inventory, which can lead to unnecessary costs such as storage fees and obsolete stock. Additionally, it allows you to prevent shortages, ensuring that your customers remain satisfied.

Fundamentals of Inventory Management

There are some fundamental principles you need to understand to effectively carry out inventory management in Excel. First, you need to have a clear picture of the demand for your products. It is important to keep track of sales figures and identify trends. You also need to be aware of your suppliers' lead times so that you can anticipate potential delays. Finally, you must ensure a good balance between inventory costs and customer satisfaction.

In addition to managing physical inventory, it is also essential to pay attention to optimizing inventory turnover. Inventory turnover refers to how quickly products are sold and replaced. By improving inventory turnover, you can enhance your business's cash flow and make room for new products. This can be achieved, for instance, by strategically placing seasonal products and planning promotions to boost sales.

Another important aspect of effective inventory management is implementing a just-in-time (JIT) inventory management system. With a JIT system, products are ordered and received only when they are needed, minimizing the costs of excess inventory. This requires close collaboration with suppliers and a well-organized logistics process to ensure that products arrive on time to meet the demand.

Excel as a Tool for Inventory Management

Excel is a powerful tool that you can use for inventory management. It offers various features and capabilities that allow you to manage your inventory efficiently. Let's take a look at why Excel is such a helpful tool for inventory management.

Why Use Excel for Inventory Management

Excel is a widely used program known for its versatility and ease of use. It enables you to organize and analyze data in a clear manner, which is particularly useful when managing your inventory. Additionally, you can utilize various formulas and functions in Excel to perform calculations and gain insight into your inventory levels.

The Benefits of Excel in Inventory Management

Excel offers several advantages for inventory management. First, you can easily keep an overview of your inventory with Excel. You can create columns for product names, stock quantities, purchase and sale prices, and more. Additionally, you can create graphs and charts using Excel to visualize trends and patterns in your inventory. This can help you make better-informed decisions.

Besides the mentioned benefits, Excel also offers the ability to set up automated alerts for specific inventory levels. By applying simple conditional formatting rules, you can set Excel to alert you when a product is running low or when a certain minimum level is reached. This way, you can take proactive measures to prevent shortages and keep your inventory in check.

Tips for Inventory Management in Excel

Now that we have a good understanding of inventory management and why Excel is a helpful tool, it's time to share some practical tips to improve your inventory management in Excel.

Setting Up Your Excel Inventory Management System

A good first step is to establish a structured Excel inventory management system. Create a worksheet with different columns for the product information you want to track. Utilize filters and sorting functions to quickly find the information you need. You can also use color codes to differentiate between product categories or priorities.

A useful addition to your Excel inventory management system is the use of dropdown menus for certain columns, such as suppliers or product categories. This helps prevent typographical errors and makes data entry more efficient. Don't forget to regularly back up your Excel file to prevent data loss.

Using Formulas and Functions for Inventory Management

One of the significant advantages of Excel is the ability to use formulas and functions to perform calculations. Use formulas to automatically update stock levels based on purchase and sales transactions. Also, use functions like SUM and AVERAGE to gain insight into the total value of your inventory and the average selling price.

In addition to standard Excel functions, you can also create custom formulas to perform specific calculations, such as determining the optimal order quantity based on demand and lead time. By customizing formulas, you can further optimize and streamline your inventory management.

Advanced Excel Tricks for Inventory Management

If you want to go beyond the basic functionalities of Excel, there are also some advanced tricks you can apply to optimize your inventory management.

In addition to using pivot tables and Excel macros, there are other advanced techniques you can apply to make your inventory management more efficient. One of these techniques is using advanced formulas and functions in Excel. By using complex formulas like VLOOKUP and IF functions, you can make Excel calculate and make decisions based on specific inventory data. This can be helpful in determining reorder levels or identifying slow-moving inventory.

Using Pivot Tables for Inventory Analysis

A pivot table is a powerful feature that allows you to summarize and analyze large amounts of data. You can use pivot tables to gain insight into your inventory levels, sales performance, and other key metrics. With just a few clicks, you can create various views and pivot based on the data you want to analyze.

Another handy application of pivot tables is visualizing your inventory data. By adding graphs and charts to your pivot table reports, you can quickly identify trends and patterns in your inventory data. This can help you make strategic decisions, such as optimizing your inventory levels or planning promotional activities.

Automating Inventory Management with Excel Macros

Excel macros are snippets of code you can write to automate certain tasks in Excel. With macros, you can automatically perform repetitive actions, such as updating stock levels. This not only saves you time but also minimizes the risk of errors. For example, you can create a macro that automatically updates your stock levels when you add new purchase or sales transactions.

An important aspect of working with Excel macros is understanding the programming language VBA (Visual Basic for Applications). By delving into VBA, you can write more complex and powerful macros that are specifically tailored to your inventory management processes. With VBA, you can create macros that import data from external sources, generate automated reports, or even interact with other software applications.

Common Pitfalls in Inventory Management with Excel

While Excel is a powerful tool for inventory management, there are also some pitfalls to watch out for.

In addition to known pitfalls, there are other aspects you need to consider when managing your inventory in Excel. For instance, it is essential to ensure a clear and consistent naming of your inventory items. This prevents confusion and errors during data entry. It is also advisable to use a separate tab or worksheet for each inventory category to maintain clarity and quickly find the information you need.

Common Mistakes and How to Avoid Them

A common mistake is forgetting to update stock levels after each purchase or sales transaction. It is important to regularly check this and ensure that your stock levels are always accurate. Another frequent mistake is relying solely on Excel as your only source of information. It is important to consult other sources and remain critical when making decisions based on Excel data.

Best Practices for Effective Inventory Management in Excel

To ensure that your inventory management in Excel remains effective, there are some best practices you can follow. Make regular backups of your Excel files to prevent data loss. Also, keep your formulas and functions up to date and ensure they work correctly. Finally, it is important to regularly evaluate and optimize your inventory management process based on new insights and changes in your business.

An additional tip is to use color codes in your Excel sheet to quickly gain insight into the status of your inventory. For example, you could use green for items that are well stocked, yellow for items that are running low, and red for items that need to be reordered urgently. These visual indicators help you take quick action and prevent issues.

Conclusion

Inventory management is a crucial part of a successful business, and Excel can be a valuable tool for efficiently managing your inventory. With Excel, you can keep a clear overview of your inventory, automate calculations, and gain insights into your inventory trends. By applying some handy tips and tricks, you can elevate your inventory management and minimize costs while maximizing customer satisfaction.

Are you ready to take your inventory management to the next level with the efficiency and convenience of ShopLinkr? Join the thousands of satisfied users who have already processed over 110,000 orders and manage your inventory and orders in one central place. Try ShopLinkr now for 14 days free and experience how easy it is to be fully set up in just 15 minutes.

Inventory management is an essential part of a successful business. It allows you to keep track of the quantity of products you have in stock, so you always have enough inventory to meet the demand of your customers. But how can you do this effectively using Microsoft Excel? In this article, we will share some handy tips and tricks that will elevate your inventory management to the next level.

Understanding Inventory Management

Before we dive into specific Excel tips, it is important to have a good understanding of inventory management and why it is so crucial for a company. Effective inventory management ensures that you always have enough products in stock to meet customer demand while simultaneously minimizing the costs of holding inventory.

The Importance of Effective Inventory Management

Effective inventory management has several benefits for a business. First, it helps you avoid having too much inventory, which can lead to unnecessary costs such as storage fees and obsolete stock. Additionally, it allows you to prevent shortages, ensuring that your customers remain satisfied.

Fundamentals of Inventory Management

There are some fundamental principles you need to understand to effectively carry out inventory management in Excel. First, you need to have a clear picture of the demand for your products. It is important to keep track of sales figures and identify trends. You also need to be aware of your suppliers' lead times so that you can anticipate potential delays. Finally, you must ensure a good balance between inventory costs and customer satisfaction.

In addition to managing physical inventory, it is also essential to pay attention to optimizing inventory turnover. Inventory turnover refers to how quickly products are sold and replaced. By improving inventory turnover, you can enhance your business's cash flow and make room for new products. This can be achieved, for instance, by strategically placing seasonal products and planning promotions to boost sales.

Another important aspect of effective inventory management is implementing a just-in-time (JIT) inventory management system. With a JIT system, products are ordered and received only when they are needed, minimizing the costs of excess inventory. This requires close collaboration with suppliers and a well-organized logistics process to ensure that products arrive on time to meet the demand.

Excel as a Tool for Inventory Management

Excel is a powerful tool that you can use for inventory management. It offers various features and capabilities that allow you to manage your inventory efficiently. Let's take a look at why Excel is such a helpful tool for inventory management.

Why Use Excel for Inventory Management

Excel is a widely used program known for its versatility and ease of use. It enables you to organize and analyze data in a clear manner, which is particularly useful when managing your inventory. Additionally, you can utilize various formulas and functions in Excel to perform calculations and gain insight into your inventory levels.

The Benefits of Excel in Inventory Management

Excel offers several advantages for inventory management. First, you can easily keep an overview of your inventory with Excel. You can create columns for product names, stock quantities, purchase and sale prices, and more. Additionally, you can create graphs and charts using Excel to visualize trends and patterns in your inventory. This can help you make better-informed decisions.

Besides the mentioned benefits, Excel also offers the ability to set up automated alerts for specific inventory levels. By applying simple conditional formatting rules, you can set Excel to alert you when a product is running low or when a certain minimum level is reached. This way, you can take proactive measures to prevent shortages and keep your inventory in check.

Tips for Inventory Management in Excel

Now that we have a good understanding of inventory management and why Excel is a helpful tool, it's time to share some practical tips to improve your inventory management in Excel.

Setting Up Your Excel Inventory Management System

A good first step is to establish a structured Excel inventory management system. Create a worksheet with different columns for the product information you want to track. Utilize filters and sorting functions to quickly find the information you need. You can also use color codes to differentiate between product categories or priorities.

A useful addition to your Excel inventory management system is the use of dropdown menus for certain columns, such as suppliers or product categories. This helps prevent typographical errors and makes data entry more efficient. Don't forget to regularly back up your Excel file to prevent data loss.

Using Formulas and Functions for Inventory Management

One of the significant advantages of Excel is the ability to use formulas and functions to perform calculations. Use formulas to automatically update stock levels based on purchase and sales transactions. Also, use functions like SUM and AVERAGE to gain insight into the total value of your inventory and the average selling price.

In addition to standard Excel functions, you can also create custom formulas to perform specific calculations, such as determining the optimal order quantity based on demand and lead time. By customizing formulas, you can further optimize and streamline your inventory management.

Advanced Excel Tricks for Inventory Management

If you want to go beyond the basic functionalities of Excel, there are also some advanced tricks you can apply to optimize your inventory management.

In addition to using pivot tables and Excel macros, there are other advanced techniques you can apply to make your inventory management more efficient. One of these techniques is using advanced formulas and functions in Excel. By using complex formulas like VLOOKUP and IF functions, you can make Excel calculate and make decisions based on specific inventory data. This can be helpful in determining reorder levels or identifying slow-moving inventory.

Using Pivot Tables for Inventory Analysis

A pivot table is a powerful feature that allows you to summarize and analyze large amounts of data. You can use pivot tables to gain insight into your inventory levels, sales performance, and other key metrics. With just a few clicks, you can create various views and pivot based on the data you want to analyze.

Another handy application of pivot tables is visualizing your inventory data. By adding graphs and charts to your pivot table reports, you can quickly identify trends and patterns in your inventory data. This can help you make strategic decisions, such as optimizing your inventory levels or planning promotional activities.

Automating Inventory Management with Excel Macros

Excel macros are snippets of code you can write to automate certain tasks in Excel. With macros, you can automatically perform repetitive actions, such as updating stock levels. This not only saves you time but also minimizes the risk of errors. For example, you can create a macro that automatically updates your stock levels when you add new purchase or sales transactions.

An important aspect of working with Excel macros is understanding the programming language VBA (Visual Basic for Applications). By delving into VBA, you can write more complex and powerful macros that are specifically tailored to your inventory management processes. With VBA, you can create macros that import data from external sources, generate automated reports, or even interact with other software applications.

Common Pitfalls in Inventory Management with Excel

While Excel is a powerful tool for inventory management, there are also some pitfalls to watch out for.

In addition to known pitfalls, there are other aspects you need to consider when managing your inventory in Excel. For instance, it is essential to ensure a clear and consistent naming of your inventory items. This prevents confusion and errors during data entry. It is also advisable to use a separate tab or worksheet for each inventory category to maintain clarity and quickly find the information you need.

Common Mistakes and How to Avoid Them

A common mistake is forgetting to update stock levels after each purchase or sales transaction. It is important to regularly check this and ensure that your stock levels are always accurate. Another frequent mistake is relying solely on Excel as your only source of information. It is important to consult other sources and remain critical when making decisions based on Excel data.

Best Practices for Effective Inventory Management in Excel

To ensure that your inventory management in Excel remains effective, there are some best practices you can follow. Make regular backups of your Excel files to prevent data loss. Also, keep your formulas and functions up to date and ensure they work correctly. Finally, it is important to regularly evaluate and optimize your inventory management process based on new insights and changes in your business.

An additional tip is to use color codes in your Excel sheet to quickly gain insight into the status of your inventory. For example, you could use green for items that are well stocked, yellow for items that are running low, and red for items that need to be reordered urgently. These visual indicators help you take quick action and prevent issues.

Conclusion

Inventory management is a crucial part of a successful business, and Excel can be a valuable tool for efficiently managing your inventory. With Excel, you can keep a clear overview of your inventory, automate calculations, and gain insights into your inventory trends. By applying some handy tips and tricks, you can elevate your inventory management and minimize costs while maximizing customer satisfaction.

Are you ready to take your inventory management to the next level with the efficiency and convenience of ShopLinkr? Join the thousands of satisfied users who have already processed over 110,000 orders and manage your inventory and orders in one central place. Try ShopLinkr now for 14 days free and experience how easy it is to be fully set up in just 15 minutes.

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date

Schedule a free demo

Clear explanation (1-on-1)

Do you want to always be informed of our latest developments?

Sign up for the newsletter.

Easily terminable

Always up-to-date